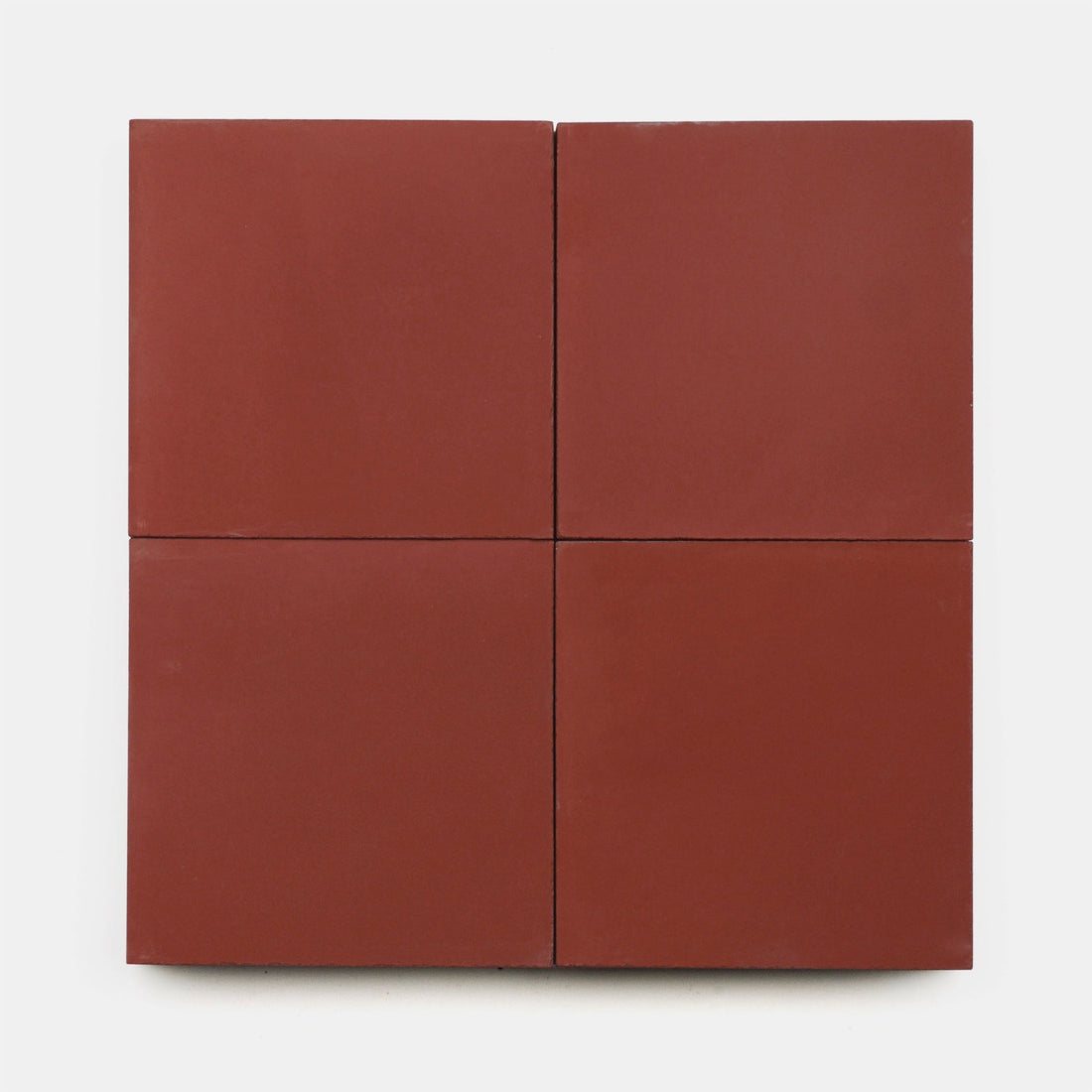

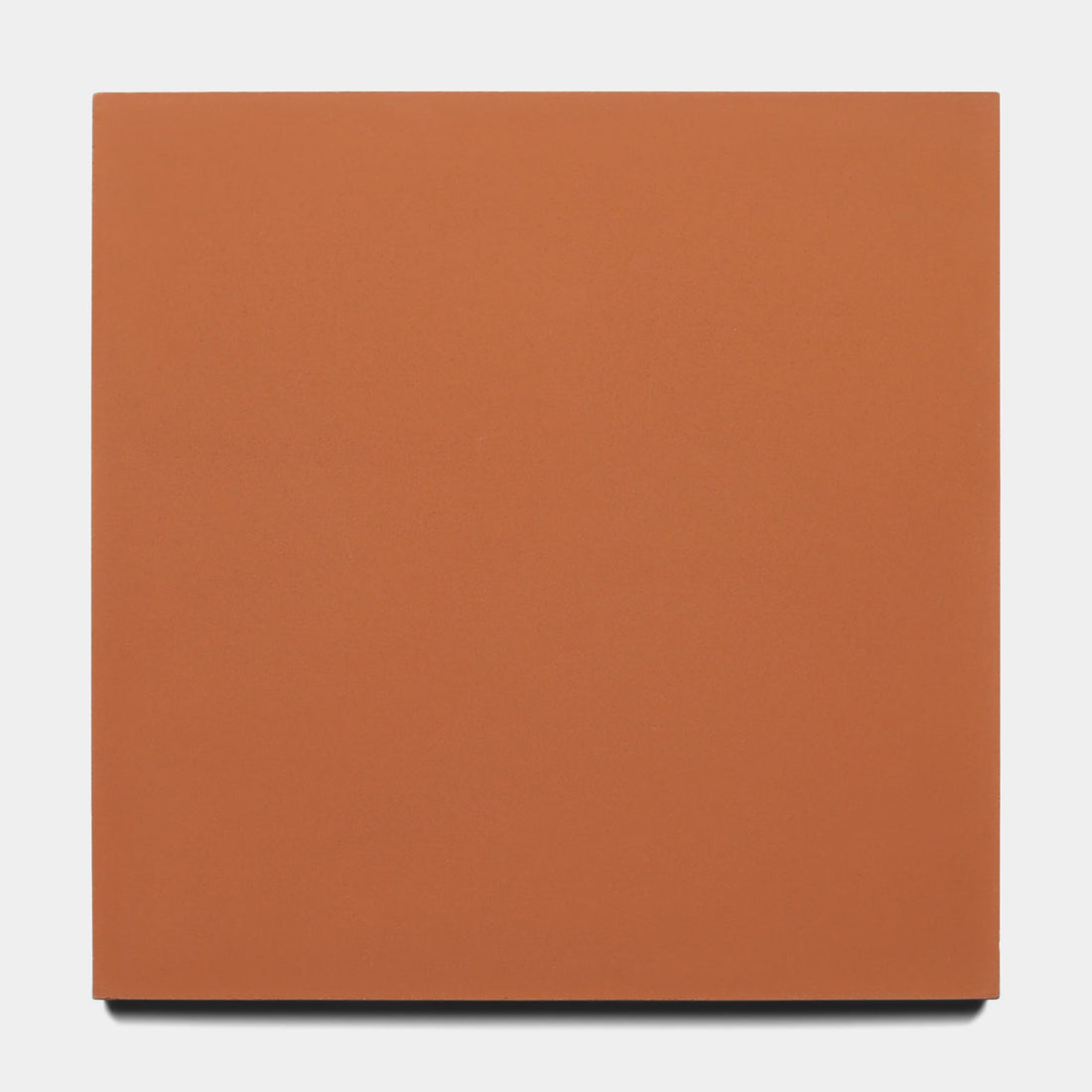

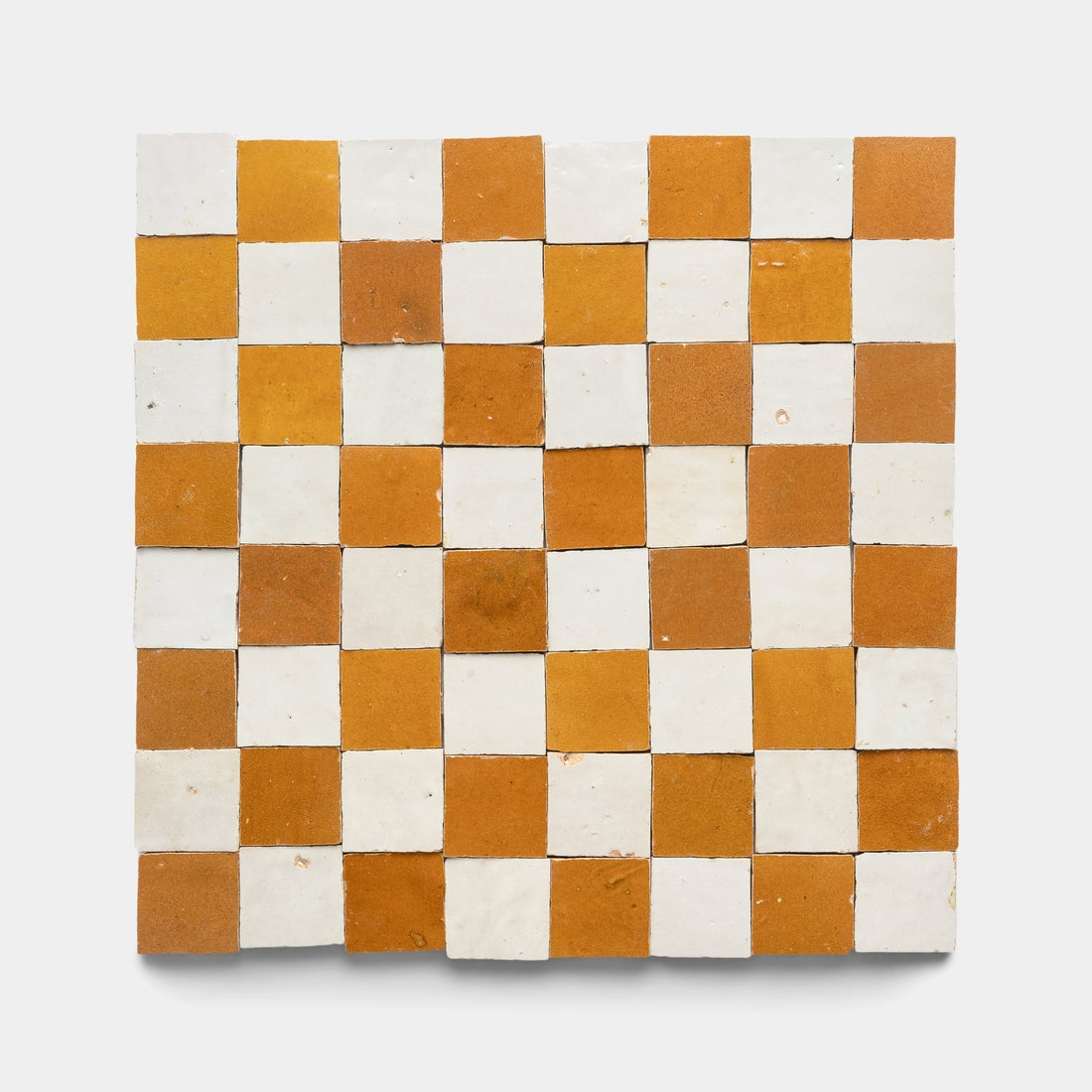

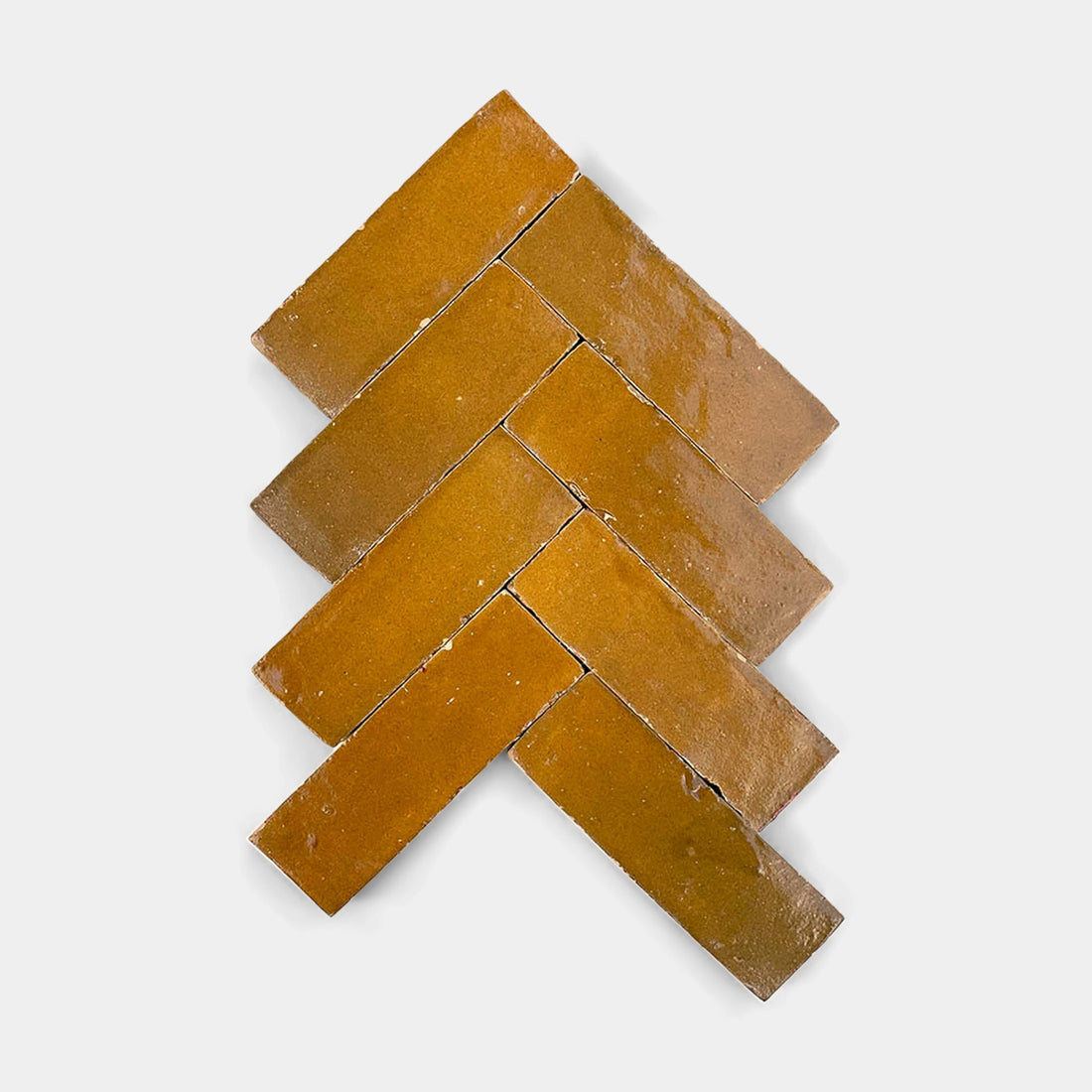

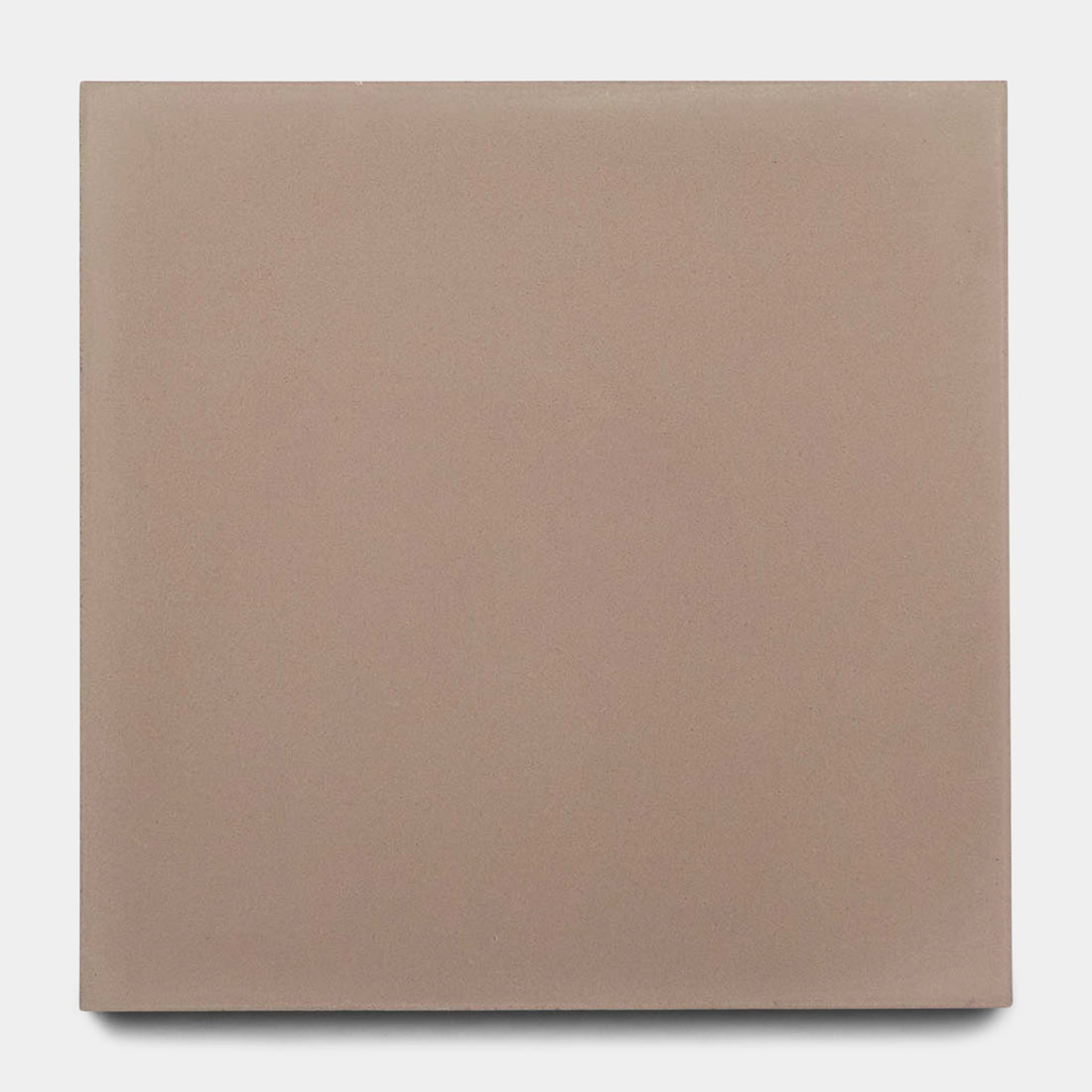

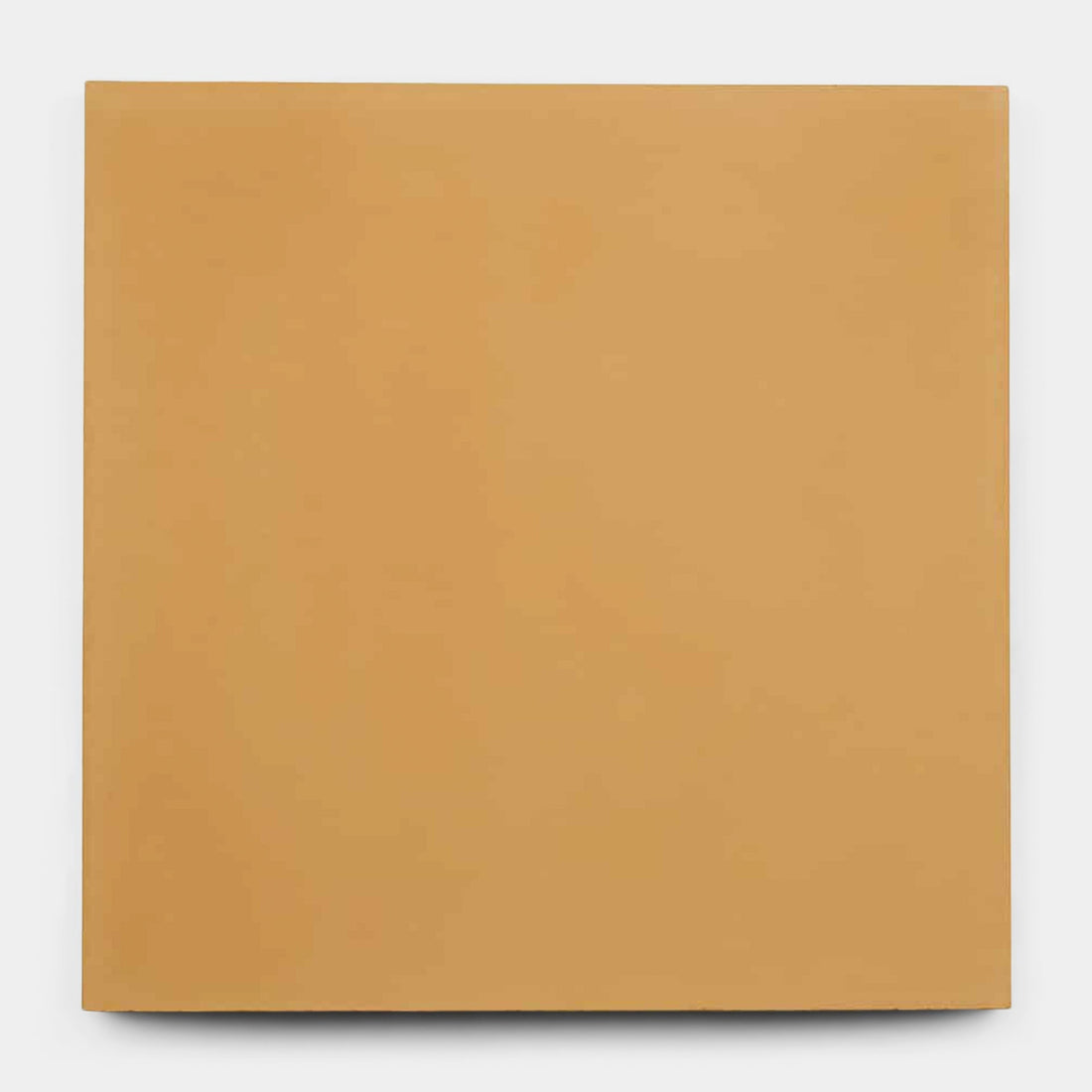

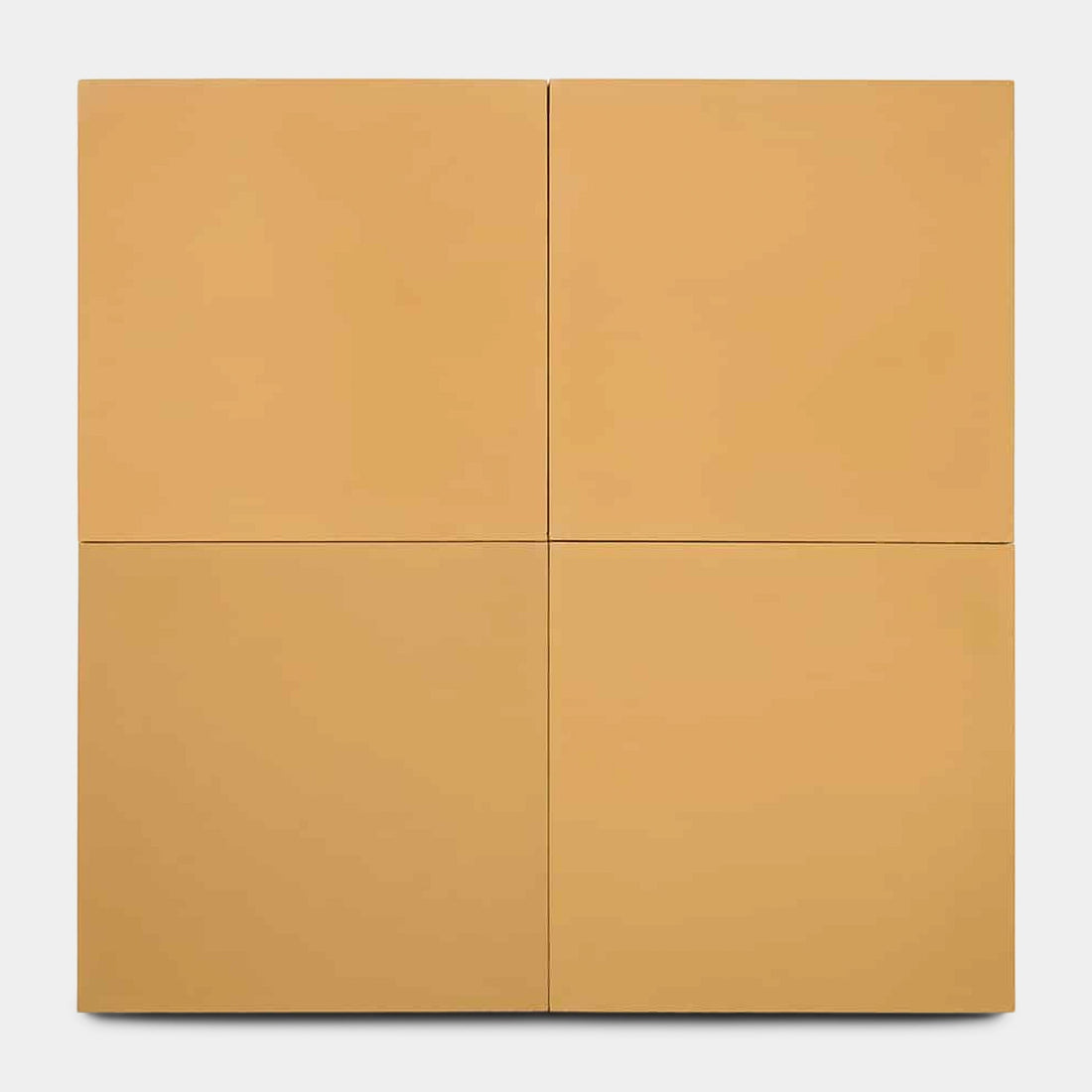

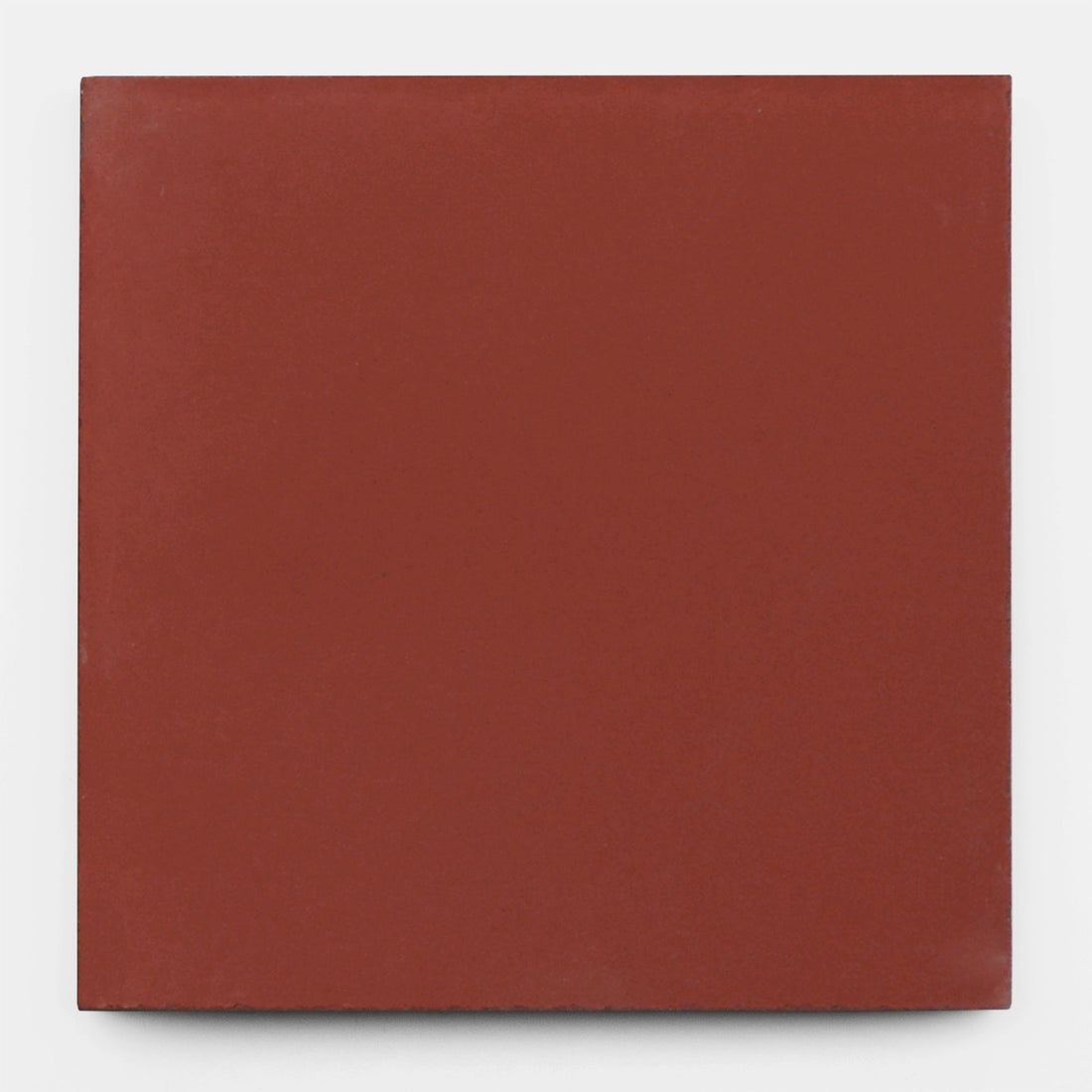

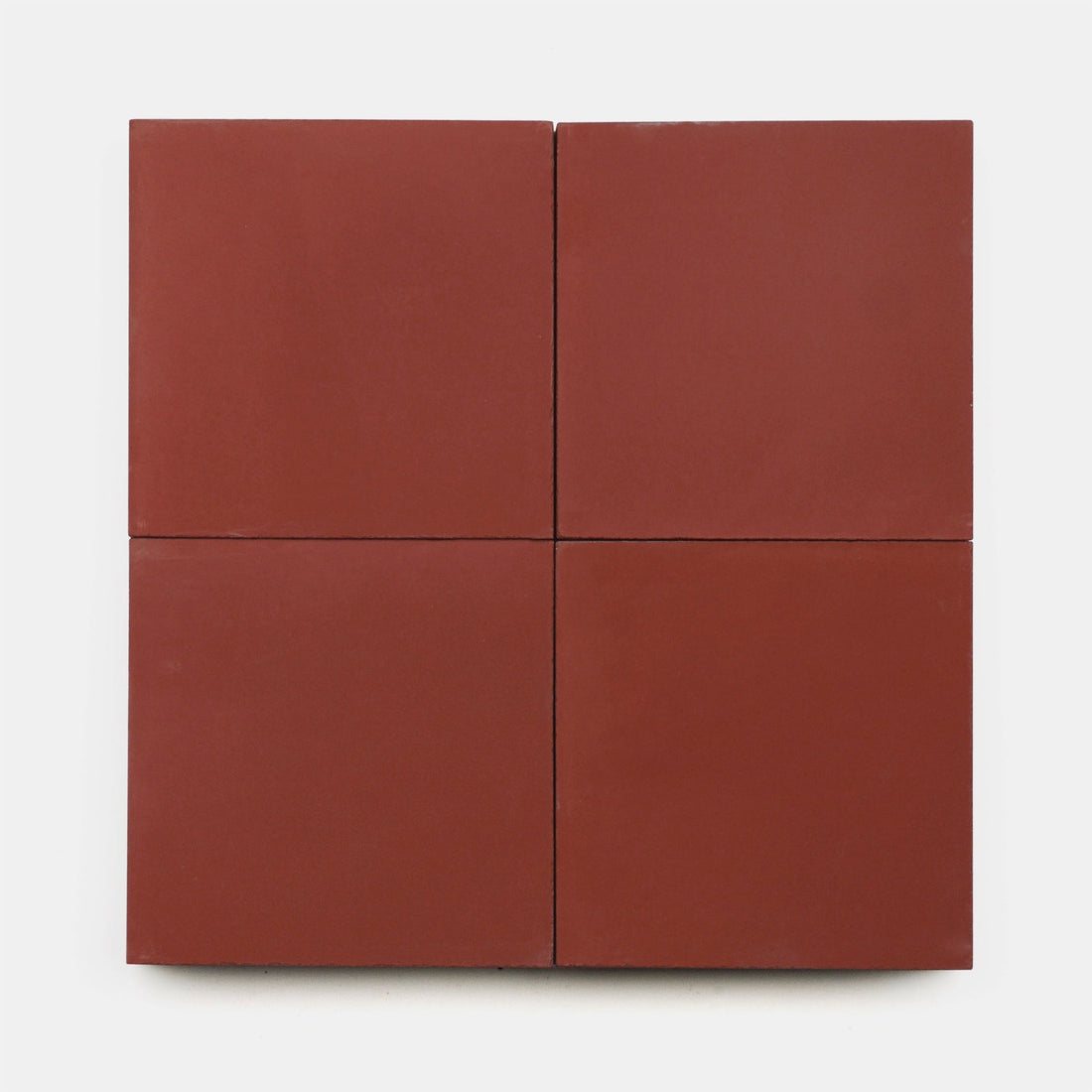

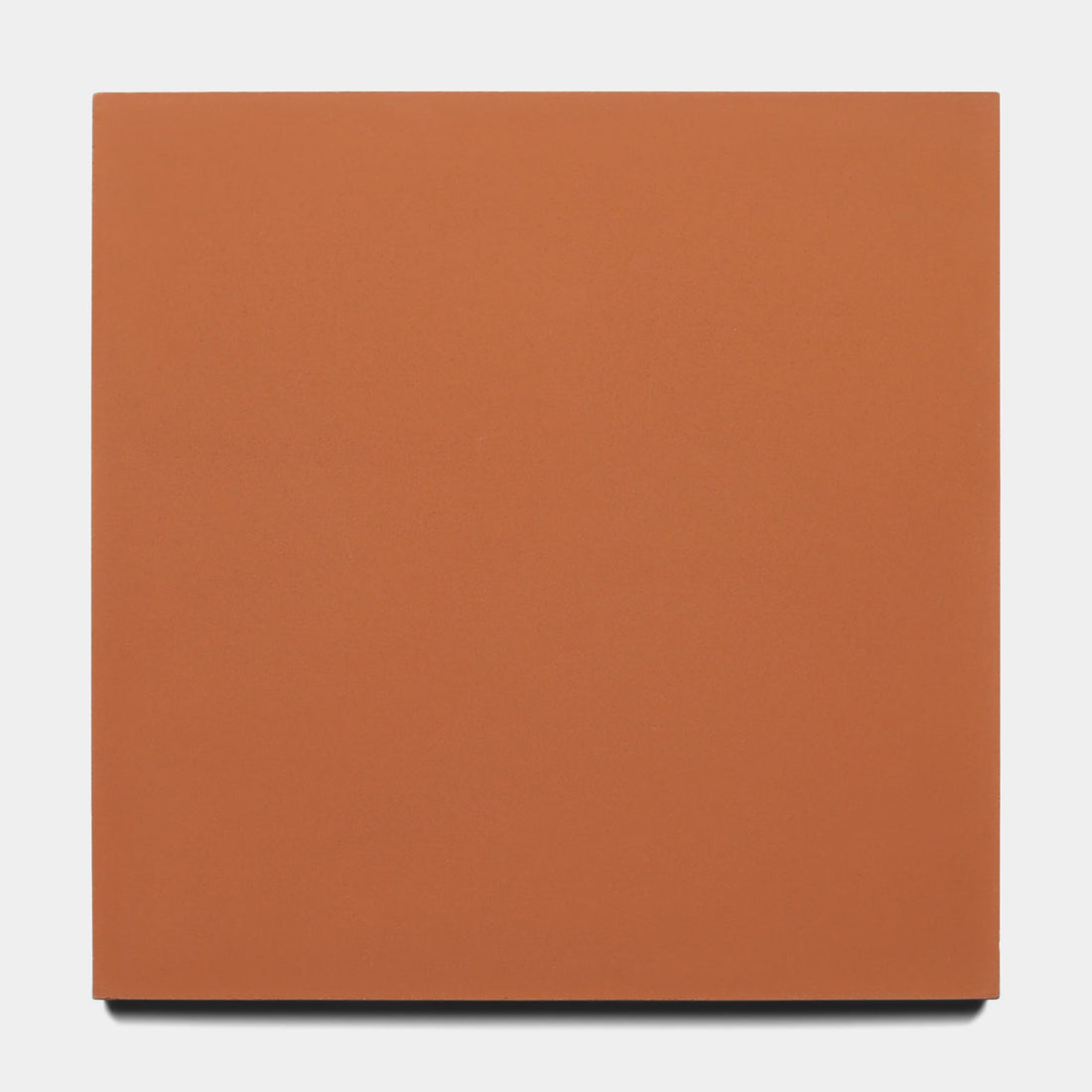

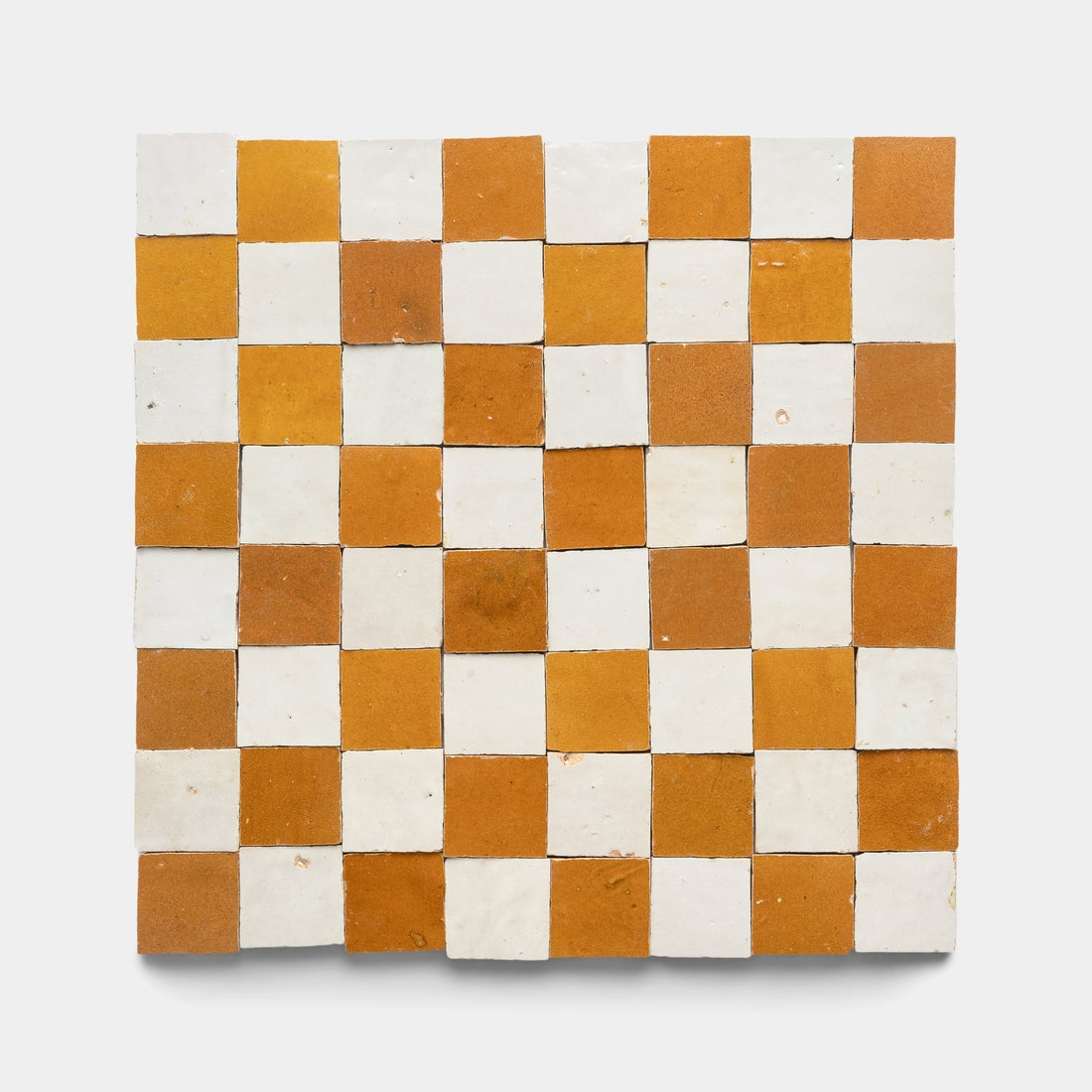

Cotto

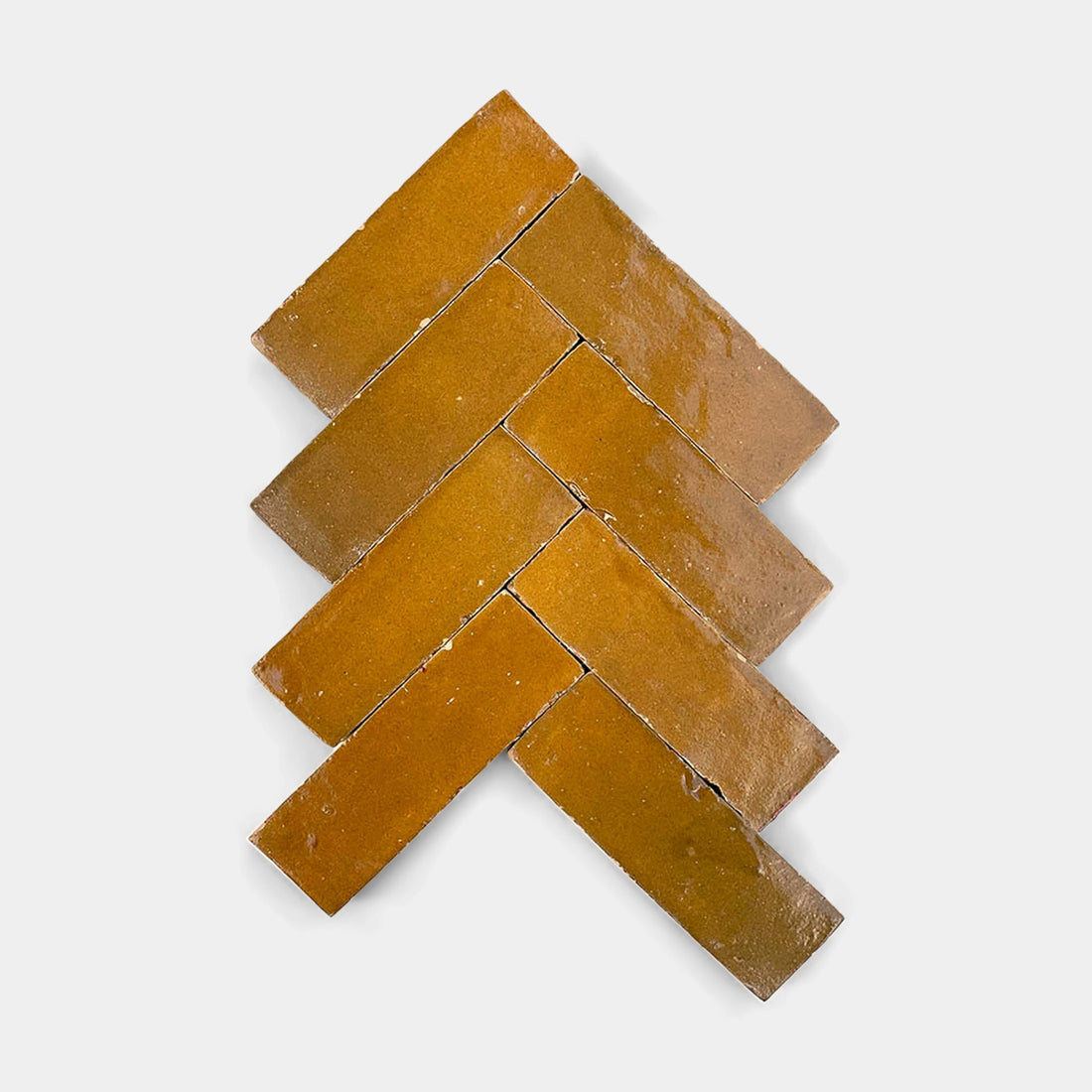

8x9 Hex + Madera

Color

Size/Shape

- 8” x 9” Hexagon

- 2” x 6” Rectangle

- 4” x 4” Square

- 6.5” x 13” Rectangle

- 8” x 8” Square

- 6" x 6" Alcazar

- 13" x 13" Big Alcazar

- Durango

- Oaxaca

- Stars & Cross

- Toltec

- Tornillo

- Zocalo

Sample Price

$3 / Sample

FULL ORDER

Price & Shipping Time

Ft² Needed

Reduce amount

Price per ft²

$19.85

Overage

Price per Tile

$8.55

# Boxes

1Total ft²

5.17

Tiles/Box

12

Total Price

$102.62

Tile Usage

-

Interior Floors – High Traffic

-

Interior Floors - Low Traffic

-

Exterior Floors – Freeze or Thaw

-

Exterior Floors - Non Freeze or Thaw

-

Interior Walls

-

Exterior Walls

-

Shower Walls + Floors

-

Pools + Spas

-

Fireplace Surround

-

Radiant Heating Compatible

-

Sealing Required

-

Interior Floors – High Traffic

-

Interior Floors - Low Traffic

-

Exterior Floors – Freeze or Thaw

-

Exterior Floors - Non Freeze or Thaw

-

Interior Walls

-

Exterior Walls

-

Shower Walls + Floors

-

Pools + Spas

-

Fireplace Surround

-

Radiant Heating Compatible

-

Sealing Required

How It's Made

Made from locally-sourced, organic clays, our hand crafted Cotto tiles are made just outside of historic San Miguel de Allende, Mexico. Elevating the storied tradition of terra cotta, modern day artisans hand form and fire each individual tile. The tiles’ clay formulation is mixed with water and blended to the ideal consistency, then pressed in a mold to dry for 1-2 weeks until the proper moisture level is achieved for firing. At this point, wood ash is added to the surface of our ‘Fired Earth’ tiles to give them their distinctive surface coloration.

About

Order & Shipping

Our in stock samples typically ship out from our Los Angeles Warehouse within 2 business days of order receipt.

Please select the Request A Sample button to add samples to your cart. All sample orders are limited to up to 4 per product design, and customers may order up to 10 samples total. The first 5 samples in your cart are complementary, and additional samples are $3 each. The credit for the first 5 samples is reflected on the final check out page. Our samples ship via FedEx or UPS, and the shipping cost is $8 for every 3 samples.

All standard full orders ship throughout the US and Canada using an LTL carrier service and are delivered on a pallet, curbside. If you live in Alaska, Hawaii, Canada or a country outside of the United States, please email us for a custom freight quote. If you are ordering multiple tile types, your full order will ship once all products are in stock.

Please note, all shipping timelines provided by LTL carriers are estimated delivery ranges. The carrier will call you to schedule a delivery date and time frame once the shipment arrives to their local delivery terminal.

We are excited to offer free Pick Up/Will Call from our Los Angeles Warehouse to help our local customers save on shipping costs! Once your order is ready, our team will reach out to you to schedule your pick up appointment.

For questions regarding your sample or full order delivery, please reach out to our team at info@ziatile.com.

Installation Guide

See more details

Details

Moderate variations in size, color, shade, and surface texture are natural characteristics of terra cotta tiles and should be expected in our Cotto line. Images shown are representative of a sample of this tile, but may not display all potential variation.

We recommend 15-20% overage to properly curate your installation and account for any cuts needed.

Size

8”

9”

Thickness

5/8”

.jpg?v=1765374608691&options=)

-

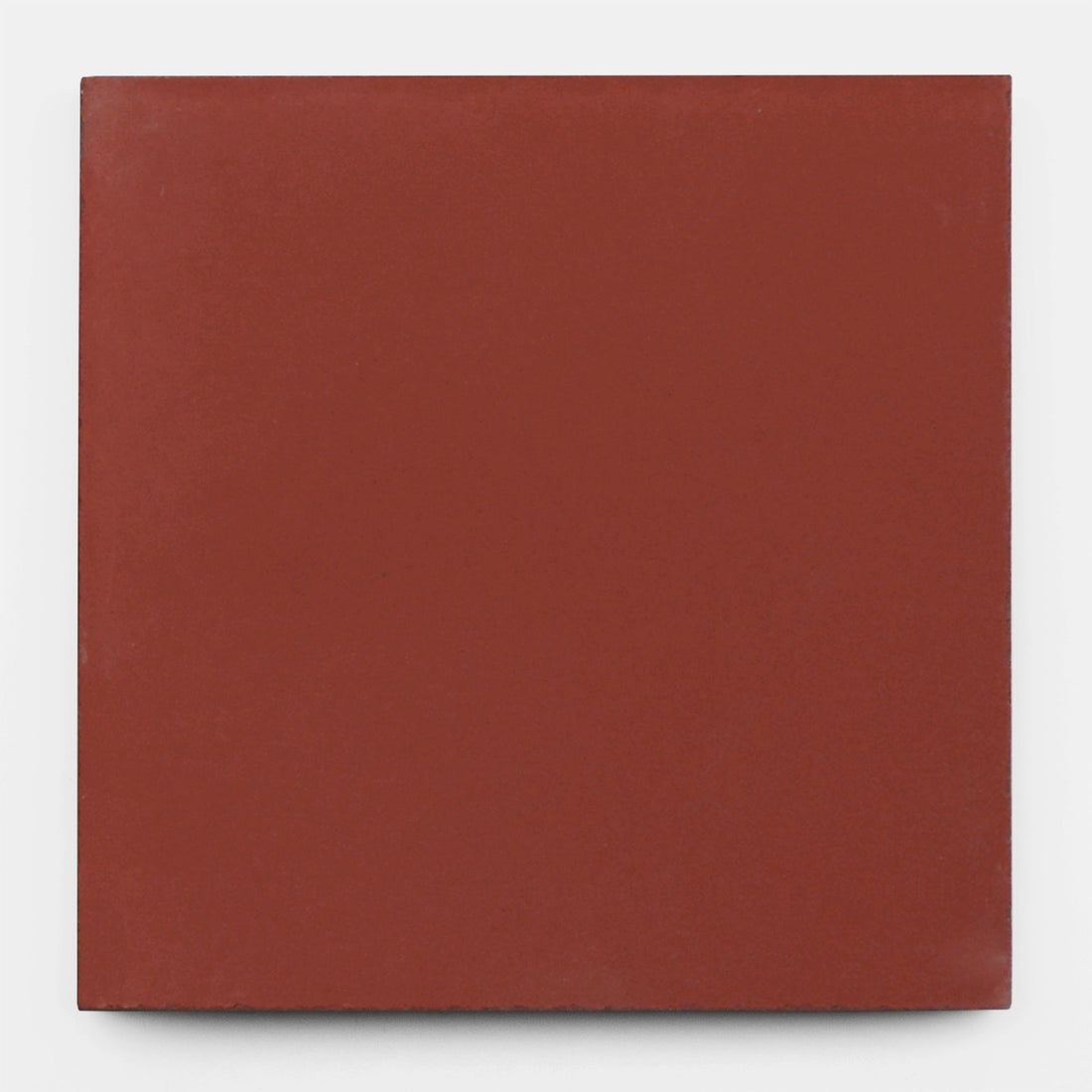

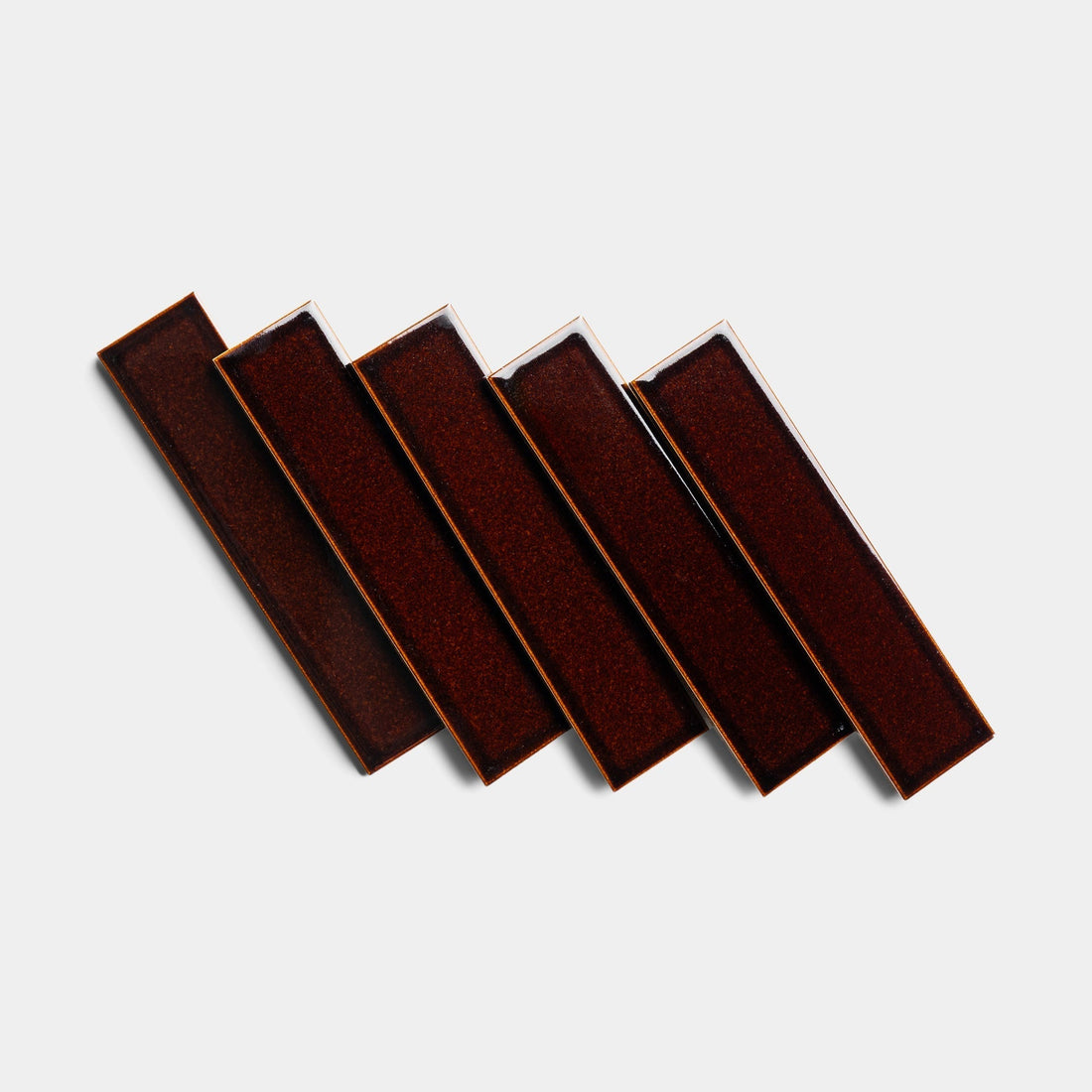

Burnt Sugar 4x4

In Stock

Zellige$19.85 / ft²

-

Amber 4x4

In Stock

Zellige$19.85 / ft²

-

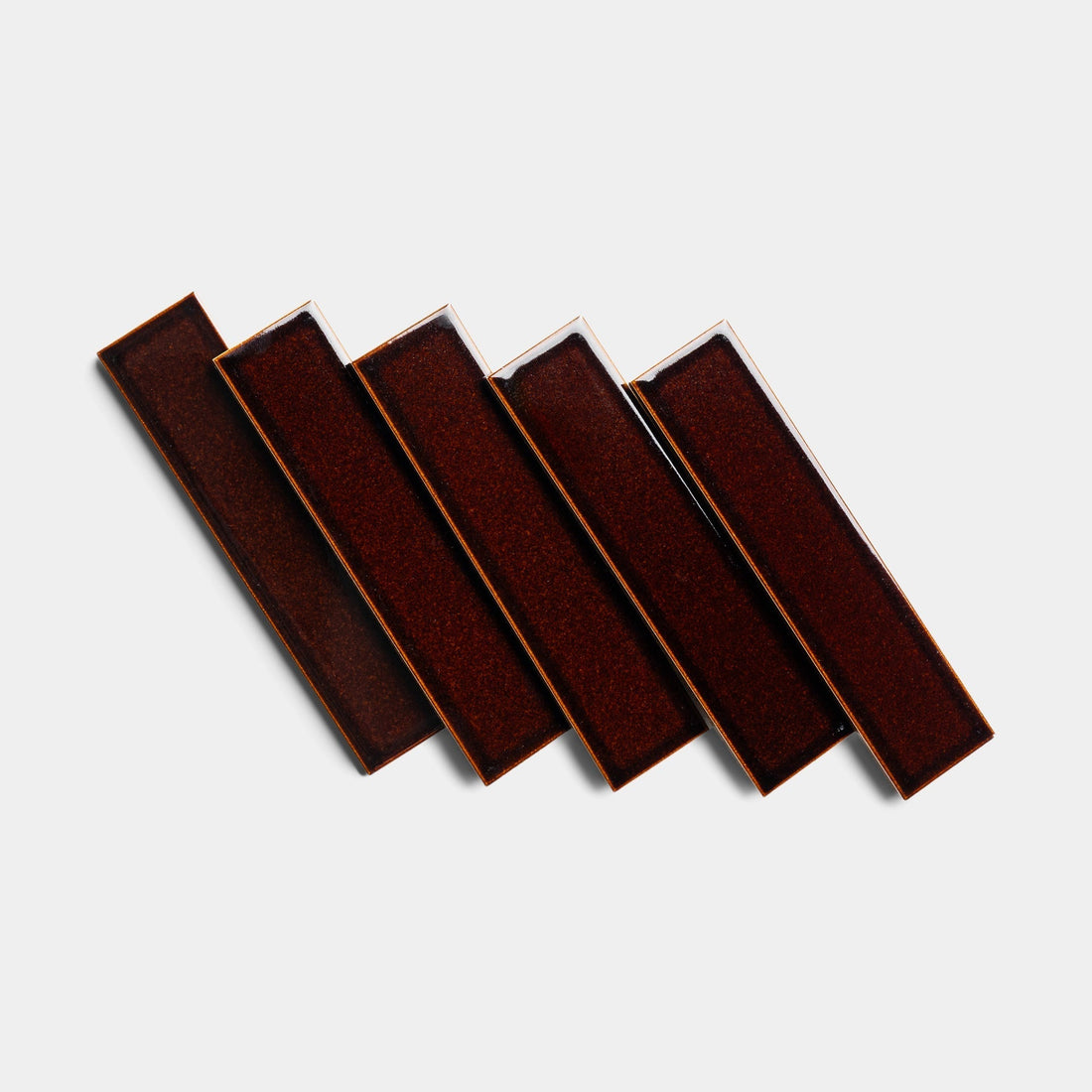

Burnt Sugar 2x6

In Stock

Zellige$19.85 / ft²

-

Burnt Sugar 2x2

In Stock

Zellige$28.85 / ft²

-

Amber 2x6

In Stock

Zellige$19.85 / ft²

-

Brownstone 4x4

In Transit

Zellige$19.85 / ft²

-

Creosote 4x4

In Stock

Cotto Allende$24.85 / ft²

-

Alcazar + Madera

In Transit

Cotto$24.85 / ft²

-

Amber 2x2

Special Order

Zellige$28.85 / ft²

-

Condesa 4x4

In Transit

Cotto Allende$24.85 / ft²

-

Molasses 4x4

In Stock

Ceramics$15.85 / ft²

-

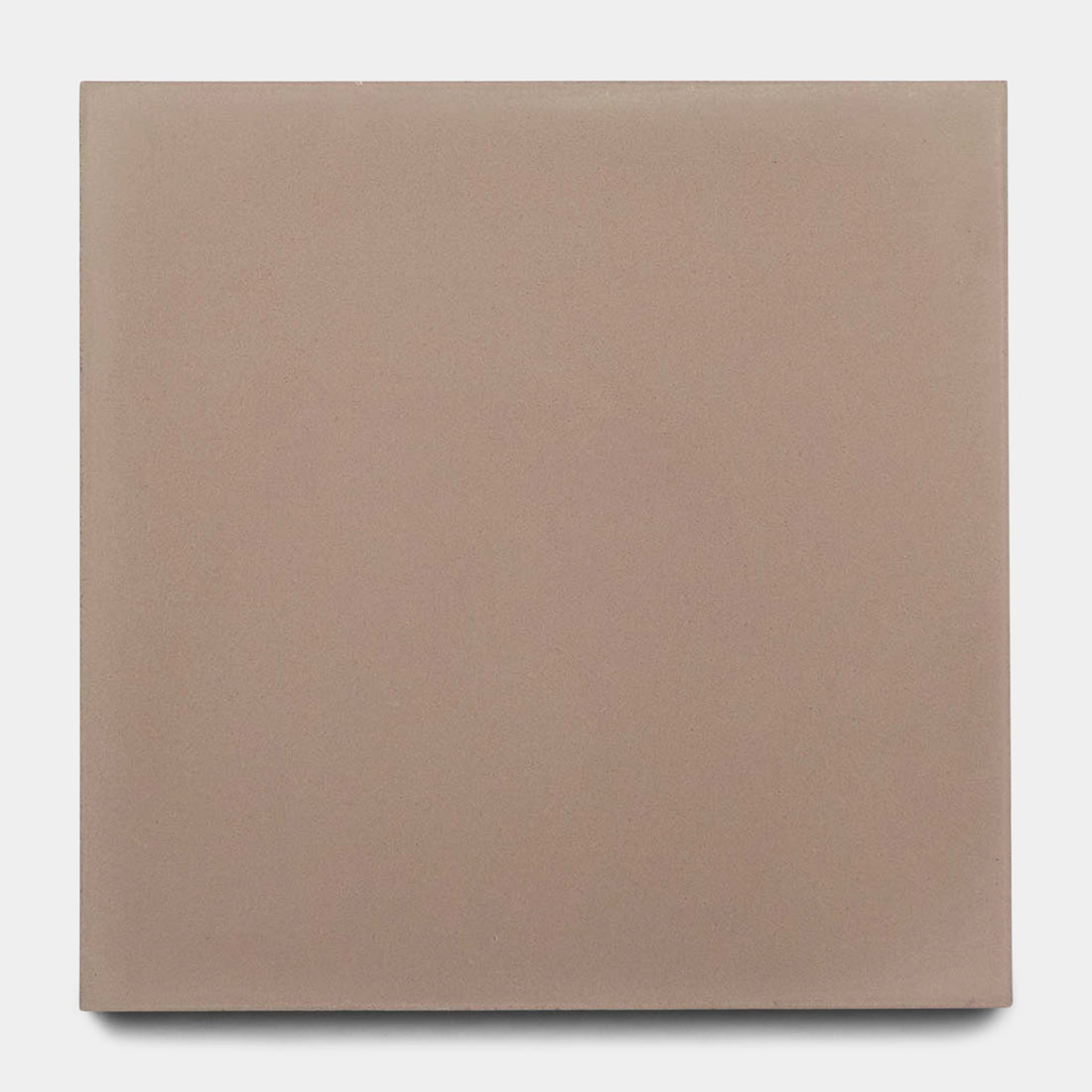

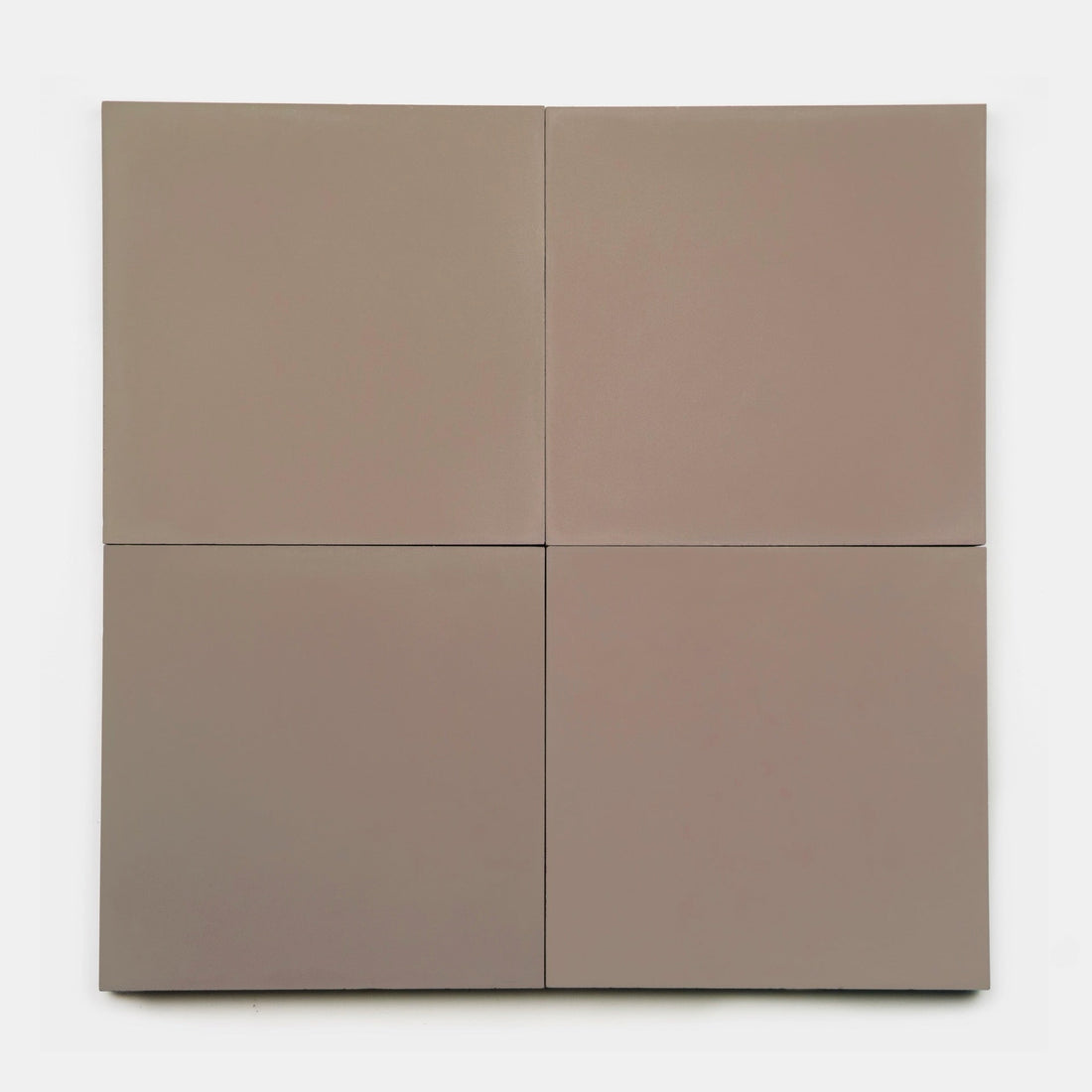

Taupe 8x8

Special Order

Cement$10.85 / ft²

-

Highball Rust 12x12

In Stock

Terrazzo$18.85 / ft²

-

Volcan 4x12

In Transit

Cantera$19.85 / ft²

-

2x6 Rectangle + Madera

In Transit

Cotto$19.85 / ft²

-

Alexander 12x12

In Stock

Terrazzo$18.85 / ft²

-

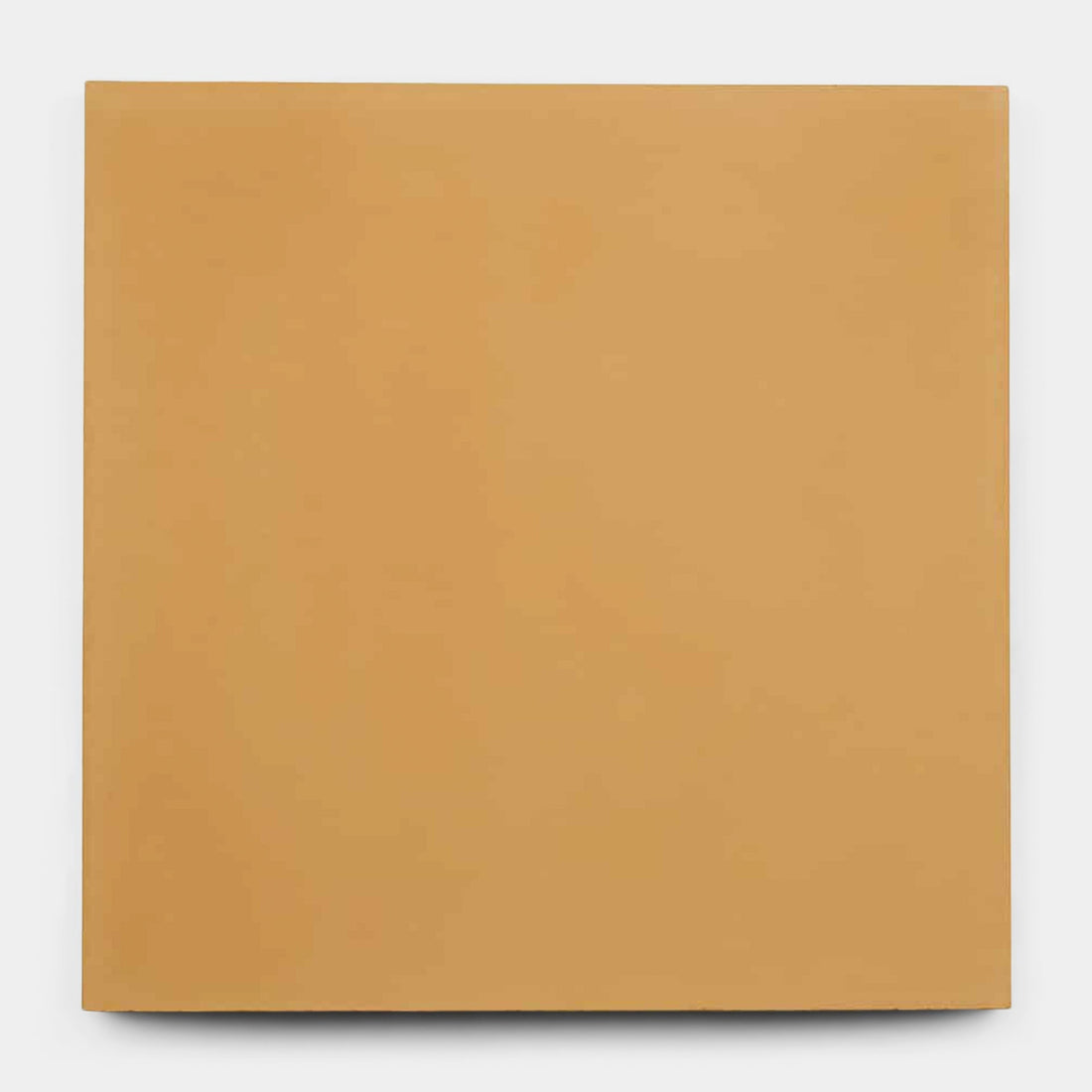

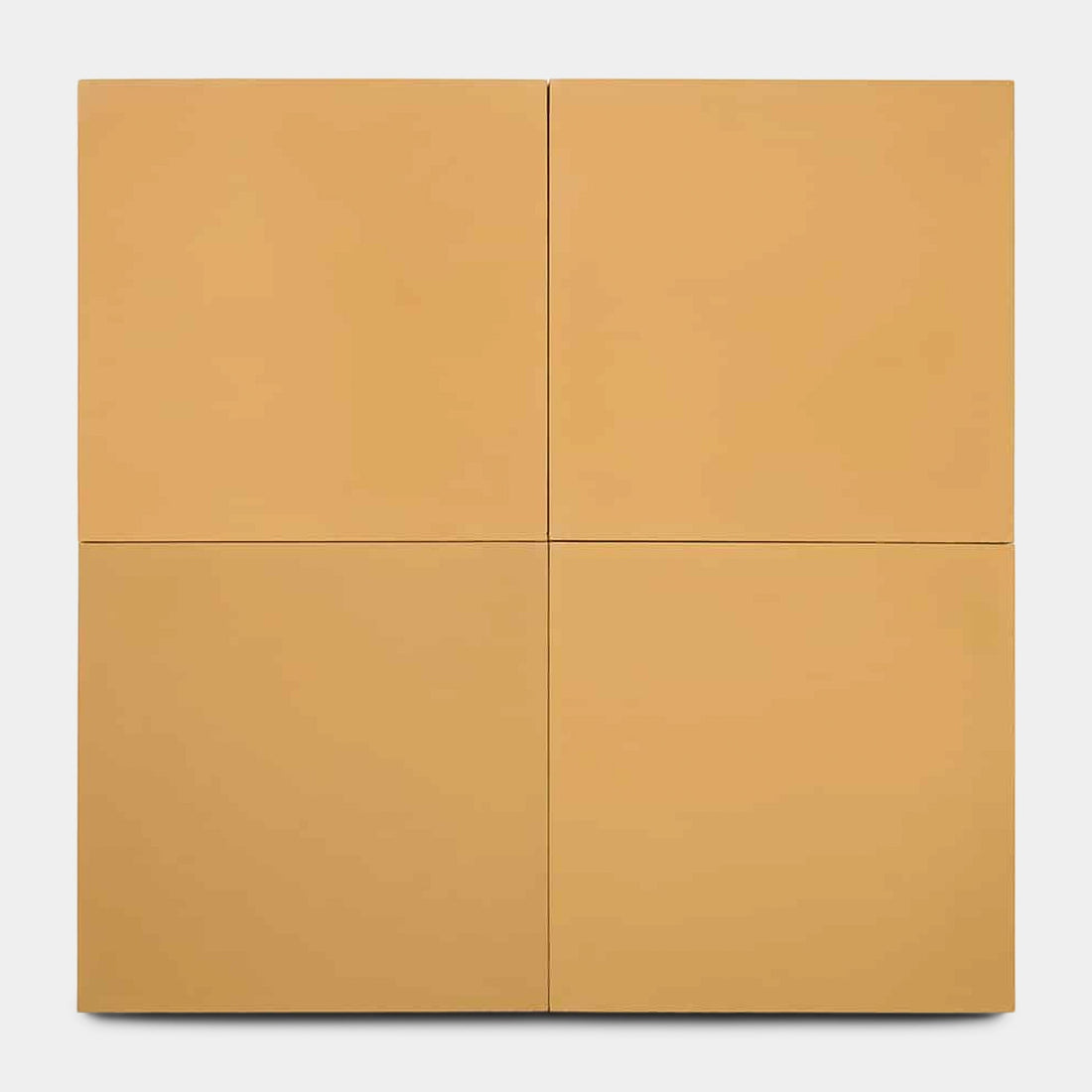

4x4 Square + Madera

In Transit

Cotto$19.85 / ft²

-

Cacao 4x4

In Transit

Cotto Allende$24.85 / ft²

-

$28.85 / ft²

-

Pompeii 8x8

In Stock

Cement$10.85 / ft²

-

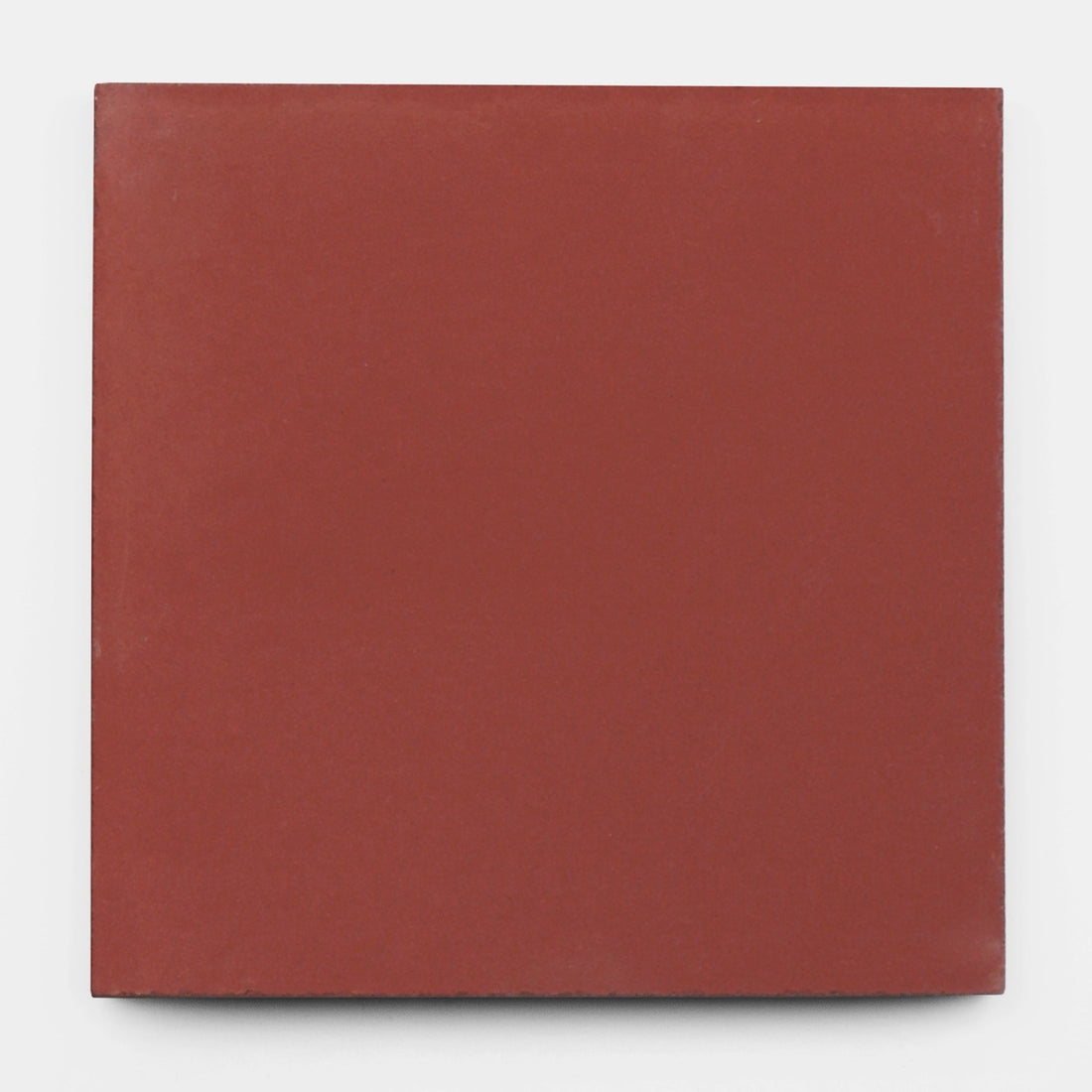

Coral 8x8

Special Order

Cement$10.85 / ft²

-

Molasses 2x8

In Stock

Ceramics$15.85 / ft²

-

Stars & Cross + Madera

In Transit

Cotto$24.85 / ft²

-

Volcan 12x24

In Stock

Cantera$19.85 / ft²

-

Ace 12x12

In Stock

Terrazzo$18.85 / ft²

-

Volcan 12x12

In Transit

Cantera$19.85 / ft²

-

Sierra 12x12

In Stock

Cantera$19.85 / ft²

-

Amber Hex

Special Order

Zellige$24.85 / ft²

-

Ginger 8x8

Special Order

Cement$10.85 / ft²

-

Rubric 5

In Stock

Zellige$38.85 / ft²

-

Sierra 4x12

In Stock

Cantera$19.85 / ft²

-

Sierra 12x24

In Stock

Cantera$19.85 / ft²

-

Chimayo 8x8

Special Order

Cement$10.85 / ft²

-

8x8 Square + Madera

In Stock

Cotto$18.85 / ft²

-

Amber Trapezoid

In Stock

Zellige$38.85 / ft²

-

Zocalo + Madera

In Stock

Cotto$19.85 / ft²

-

6.5x13 Rectangle + Madera

In Stock

Cotto$19.85 / ft²

-

Brownstone Hex

Special Order

Zellige$24.85 / ft²

-

Sierra 24x24

In Stock

Cantera$19.85 / ft²

-

8x9 Hex + Madera

In Stock

Cotto$19.85 / ft²

-

Volcan 24x24

In Stock

Cantera$19.85 / ft²

-

Burnt Sugar Hex

Special Order

Zellige$24.85 / ft²

-

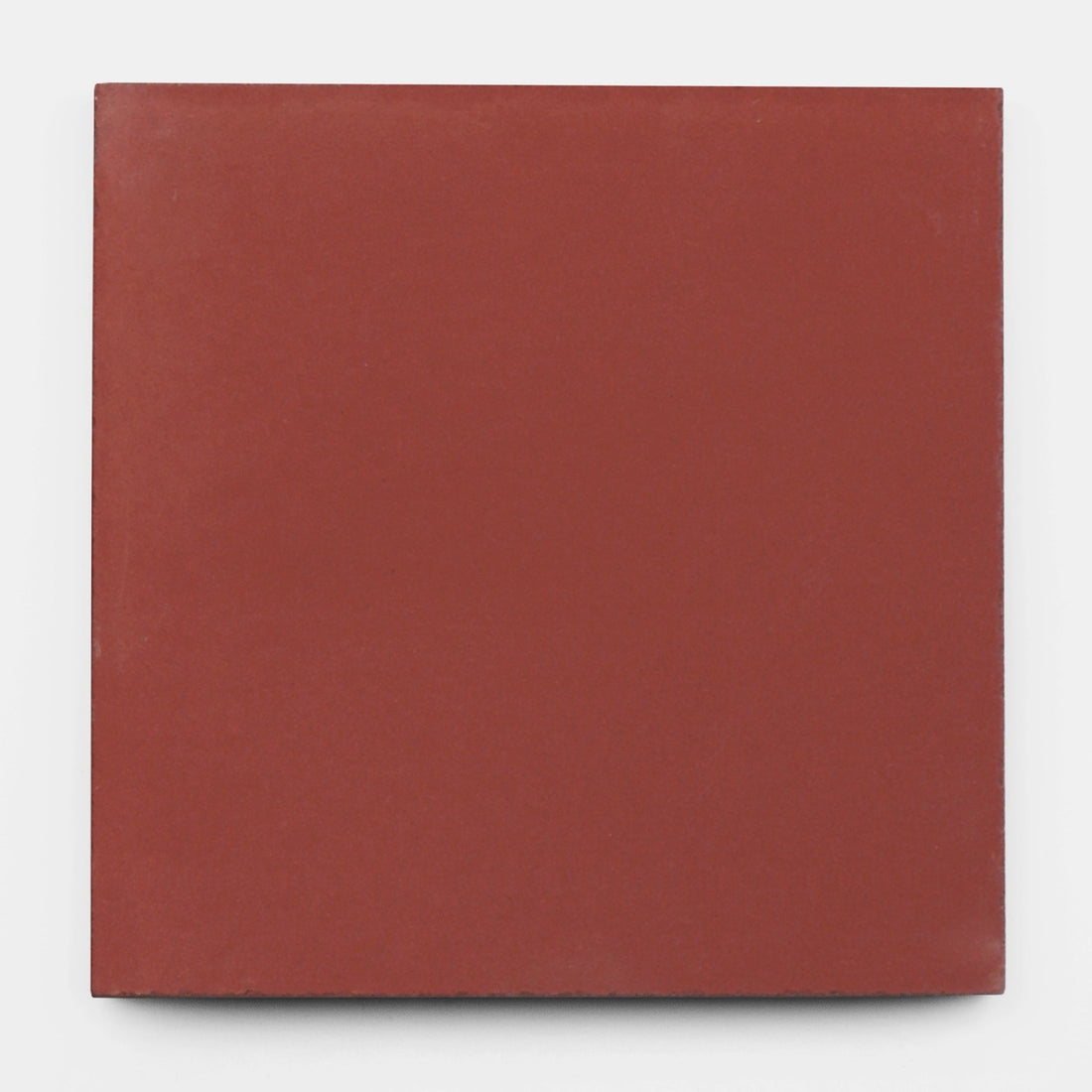

Rust 8x8

In Stock

Cement$10.85 / ft²

-

Durango + Madera

In Transit

Cotto$24.85 / ft²

-

Molasses 2x4

In Stock

Ceramics$16.85 / ft²

-

Toltec + Madera

In Stock

Cotto$19.85 / ft²

-

Pompeii 4x4

In Stock

Cement$15.85 / ft²

-

Artemis 12x12

In Transit

Terrazzo$18.85 / ft²

-

$28.85 / ft²

-

San Juan Taupe 8x8

In Stock

Cement$15.85 / ft²